News classification>>

The principle of automatic packaging machine?

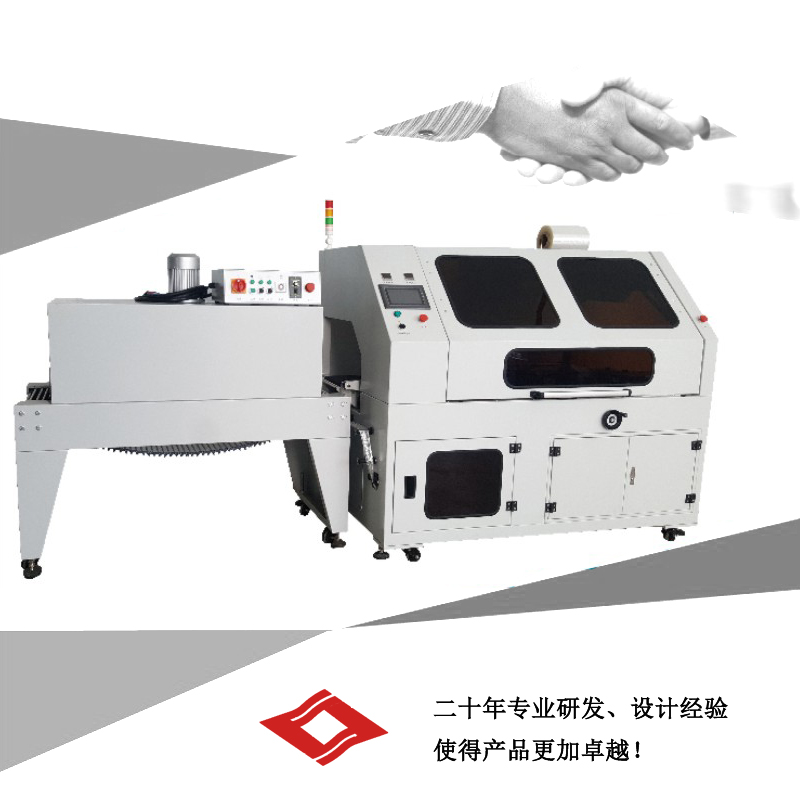

Fully automatic packaging machines are widely used in food, chemical, pharmaceutical, light industry and other industries. It is now mainly used for the packaging of solid shaped items such as instant noodles, moon cakes, ice cream, chocolate, egg yolk pie, egg rolls, bread, sausages, frozen foods, and medicine. So the automatic packaging machine is so widely used in our lives, how does it work? Today, Kesheng Xiaobian takes you into the world of automatic packaging machines.

With the improvement of automation, people's living standards have been greatly improved. Both the use and technology of the packaging machine have been improved. The use of automation technology reduces the professional skill requirements of older operators. The quality of the product packaging is closely related to the temperature system, the accuracy of the host speed, and the stability of the tracking system. So what is the tracking system? The tracking system is the control core of the packaging machine, and the forward and reverse two-way tracking is used to further improve the tracking accuracy.

The use of the tracking system can compensate and correct the errors in the production process of the packaging materials in time, avoiding the waste of packaging materials. If the technical requirements are not met after the predetermined number of tracking, the machine can be automatically stopped for inspection to avoid the generation of waste products. Due to the use of frequency conversion speed regulation, the chain transmission is greatly reduced, the stability and reliability of the machine operation are improved, and the operation is reduced. The noise of the machine running. It ensures the high-tech, high-efficiency and high-tech level of the packaging machine with high efficiency, low loss and automatic detection. In addition to the automatic packaging machine, some additional configurations are essential on the fully automatic packaging machine, such as the date batch number coding machine, the configuration of various feeding systems, the middle seal structure design, the inflation configuration, etc. There are a number of additional configurations to assist our fully automated packaging machine to work. This kind of anti-counterfeiting packaging appearing in the shopping mall is the result of the development efforts of our fully automatic packaging machine, which not only ensures the uniqueness of the manufacturer's production brand, but also ensures that the consumer can recognize the product identification when purchasing. Buy a safe product.